About DOVMXTECH

WHO WE ARE?

DOVMXTECH is a world famous brand in the field of Reaction separation equipment.

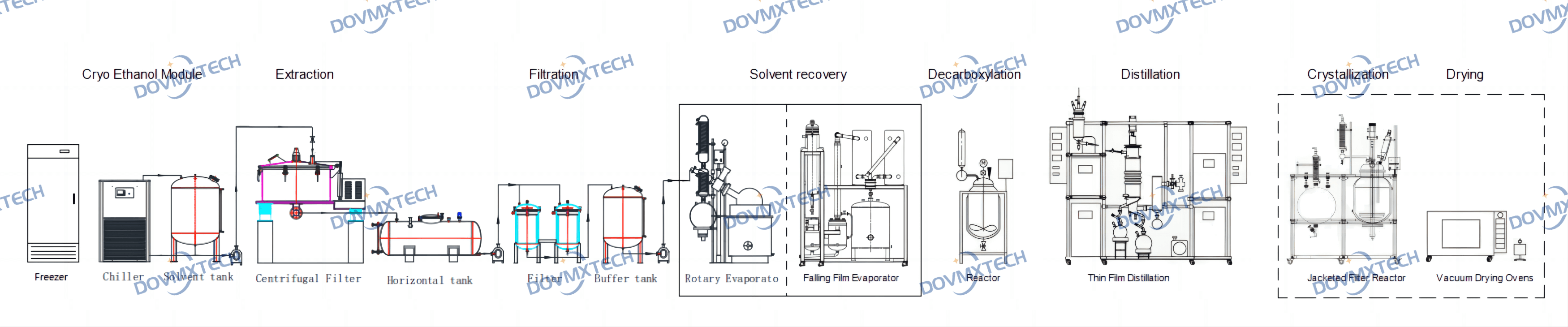

DOVMXTECH supply the highest quality of hemp Extraction System, Distillation System (Wiped Film Molecular Distillation, CBD Distillation, Short Path Distillation system), CBD Separation, Centrifugal Extractor, and Falling Film Evaporator turnkey solutions with the cutting-edge equipment at affordable pricing.

DOVMXtech not only provide relevant equipment for CBD oil, Fish oil or Essential oil extraction and distillation, such as Molecular Distillation, Thin Film Evaporator, Centrifuge Extractor, Rotary Evaporator, Stainless Steel Reactor, Glass Reactor, Temperature Control, Vacuum Control, Distillation and Reaction System, including Water Circulating Vacuum Pump, Diaphragm Vacuum Pump, Dynamic Temperature Control System, Recirculating Chiller, Stirring Reaction Bath, High Temperature Circulator and Magnetic Stirrer, etc.

We also provide turnkey solution for CBD oil, Fish oil or Essential oil extraction and technical support.

"DOVMXtech" products can be used in fields like chemical, biological, pharmaceutical industries, new materials, new energy, electronics, metallurgy, petroleum, mechanics, etc., which have been exported to Asia, Europe, America, Australia and covered many universities, scientific research institutes and laboratories worldwide.

Why DOVMXTECH is the first choice of CBD oil, Fish oil or Essential oil separation and extraction equipment?

17 years of manufacturing experience!

A large number of engineering installation cases!

High quality at reasonable price!

Professional technical support, after-sales and installation guidance!

Flexible Customization! Fast Delivery!

Founded in 2005, Dovmxtech factory is located in Kunshan City, Jiangsu Province, China. It is near Shanghai and has convenient transportation.

Covering an area of more than 5000 square meters, Dovmxtech factory not only has a senior design and R & D department, but also has strong production capacity.

The factory has independent glass processing workshop, stainless steel welding workshop and parts production and processing workshop, which can ensure fast delivery time and flexible customization ability.

Dovmxtech has a group of senior technical experts to ensure high quality standards in the process of technology development, mechanical design and manufacturing. Our experts offer experience and data-based advice about our product line.

Dovmxtech has formed a strong sales channel and perfect after-sales system, and its products are exported to home and abroad. We have participated in many well-known exhibitions around the world, like MJBizCon Las Vegas, USA.

The products are mainly exported to North America, Europe, Southeast Asia and other countries and regions.

Through the cooperation of all the participating departments, Dovmxtech manufactured the world's largest glass short-range evaporator with evaporation area of 0.65 ㎡.

OEM & ODM Service

We follow your specifications and ideas in formulating long-running extraction reaction separation equipment.

Quality Products

Meeting strict standards, our product line has been inspected for flaws and optimized to function.

Proved Safety

From over-temperature alarms to overload protection, our products are for safe lab and industry uses.

Cost-saving

Through our control over the production and the long service of our product line, you will spend less.

On-time Response

Within 24 hours, we provide an immediate reply to all of your questions and prioritize requests.

In addition to providing systems and components of thin film evaporators and short-range distillation equipment - Molecular Distillation, Dovmxtech can also provide laboratory and pilot-scale laboratory equipment for customers, such as Rotary Evaporator, Stainless Steel Reactor, Glass Reactor.

Dovmxtech's main products are Wiped Film Molecular Distillation, Rotary Evaporator, Glass Reactor, Stainless Steel Reactor, falling film evaporator, Centrifuge Extractor, Filtration equipment, Suction filter, bioreactor, plant extractors, various reactors, temperature control equipment and other supporting equipment, which can be sold as a complete set of equipment or as a separate component (such as distillation body).

Dovmxtech equipment and equipment for purification, concentration, removal of impurities, color improvement, etc., suitable for a variety of industries.

Thin film evaporation and short path distillation equipment are most commonly used in chemical, pharmaceutical and food industries.

●

Purification of aromatic oil, purification of polymer intermediates, extraction of lanolin, etc.

●

Concentration and purification of essential oils such as agar wood, rose and hemp.

●

Refined fish oil, deacidification of fats, refined high-carbon alcohols, separation of mixed fats, etc.

●

Refining and decolorizing erucic acid, linoleic acid, linolenic acid, dimer acid, etc.

●

Removal of monomer phenol in phenolic resin.

●

Puification after plant extraction (supercritical, carbon dioxide, butane, hydrocarbons, ethanol, etc.)

●

Separation of heavy molecular substances and metal ions in fine chemicals.

●

Separation and purification of active ingredients of crude Chinese medicines and synthetic medicines such as vitamins, unsaturated fatty acids, volatile oils, etc.

●

Removes chlorophyll, phytosterols, pesticides, fats and waxes.

Molecular Distillation

Molecular distillation is used to separate high boiling point, heat sensitive and easily oxidizable substances.

Molecular Distillation is a special liquid-liquid separation technology, which is different from traditional distillation on the difference boiling point. This is a kind of distillation in high vacuumenvironment, for the difference of material molecular movement free path, was carried out in the heat sensitivematerial or high boiling point material distillation and purification process. Short Path Distillation is mainly used in chemical, pharmaceutical, petrochemical, spices, plastics, oil and other fields.

| (DOVMXtech molecular distillation) | ||||||

| Model | FMD-60 | FMD-80 | FMD-100 | FMD-150 | FMD-200 | FMD-230 |

| Evaporation area (M2) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Reference handling capacity(L/H) | 0.5-1.0 | 1.0-5.0 | 2.0-10 | 3.0-15 | 4.0-20 | 6.0-30 |

| Feed tank volume(L) | >2.0 | >2.0 | 3 | >3.0 | >5.0 | >10.0 |

| Feeding method | Manual knob valve feed (default) | |||||

| Peistaltic pump feed (optional) | ||||||

| Gear pump, automatic continuous feeding, adjustable speed (optional) | ||||||

| Discharge method | Discharge after shutdown (default) | |||||

| Manual discharge (optional) | ||||||

| Gear pump, automatic continuous discharging , adjustable speed (optional) | ||||||

| Vacuum (mbar) | (Reachable) 0.001 mbar | |||||

| Speed range (rpm) | 0-450 | 0-300 | ||||

| Operating temperature | (The highest temperature can reach) 300°C | |||||

| Insulation method | Heating with electric heating tape | |||||

| Double jacket, heated with heat transfer medium | ||||||

Thin film evaporator is a highly efficient device for evaporation and distillation, which uses scraper system to force the liquid film forming. Its features high heat transfer efficiency, fast evaporation speed and short material residence time. It can be widely used for the evaporation of heat-sensitive substances.

| (DOVMXtech glass thin film evaporator) | ||||||

| Model | TFE-60 | TFE-80 | TFE-100 | TFE-150 | TFE-200 | TFE-230 |

| Evaporation area (M2) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Reference handling capacity(L/H) | 0.5-3.0 | 1.0-8.0 | 3.0-15 | 5.0-20 | 6.0-30 | 10.0-50 |

| Feed tank volume(L) | >2.0 | >2.0 | 3 | >3.0 | >5.0 | >10.0 |

| Feeding method | Manual knob valve feed (default) | |||||

| Peistaltic pump feed (optional) | ||||||

| Gear pump, automatic continuous feeding, adjustable speed (optional) | ||||||

| Discharge method | Discharge after shutdown (default) | |||||

| Manual discharge (optional) | ||||||

| Gear pump, automatic continuous discharging , adjustable speed (optional) | ||||||

| Vacuum (mbar) | (Reachable) 0.5mbar | |||||

| Speed range (rpm) | 0-450 | 0-300 | ||||

| Operating temperature | The highest temperature can reach 300°C | |||||

| Insulation method | Heating with electric heating tape | |||||

| Double jacket, heated with heat transfer medium | ||||||

Rotary evaporators are mainly used for concentration, crystallization, drying, separation and solvent recovery in the pharmaceutical, chemical and biological pharmaceutical industries. The principle is to heat the rotating bottle at a constant speed under vacuum conditions, so that the material forms a large-area film on the bottle wall and evaporates efficiently. The solvent vapor is cooled by a high-efficiency glass condenser and recovered in the collection bottle, which greatly improves the evaporation efficiency.

Rotary evaporators are essential tools used for evaporation, distillation, and solvent recovery. Not only are they seen in research and process laboratories but are also utilized in food and beverage production.

DOVMXtech has been producing quality rotary evaporators over 17 years. We offer different rotary evaporators capacity from 2 liters up to 50 liters, all of which provide high distillation rates at an affordable price. and offer various rotary evaporators with unique features such as an electric lifter.

For reliable rotary evaporators, our equipment can produce optimal results thanks to the precise controls, superior glass materials, and other useful features. We can manufacture a unit that is in demand among the pharmaceutical, biotechnology, chemistry, and laboratory industry.

Laboratory Rotary Evaporator

1L 2L

DOVMXtech-1001VN DOVMXtech-3001

Large Rotary Evaporator

5L 10L 20L

DOVMXtech-1005CE DOVMXtech-1005Ex DOVMXtech-1010CE DOVMXtech-1010Ex DOVMXtech-1020CE DOVMXtech-1020Ex

Industrial Rotary Evaporator

50L

DOVMXtech-1050CE DOVMXtech-1050Ex

| Model DOVMXtech-RE | 1001VN | 3001 | 1005CE | 1005Ex | 1010CE | 1010Ex | 1020CE | 1020Ex | 1050CE | 1050Ex | |

| Evaporating flask(L) | 0.5 / 1 | 0.5 / 1 | 5 | 10 | 20 | 50 | |||||

| Receiving flask (L) | 1 | 1 | 3 | 5 | 10 | 20 | |||||

| Speed-regulation | Continuously variable | ||||||||||

| Power supply | 220-240V, 50/60Hz | 220-240V, 50/60Hz | 220-240V, 50/60Hz | 380V, 50Hz or 220V, 60Hz | 380V, 50Hz or 220V, 60Hz | ||||||

| Heating power (kW) | 1.05 | 1.3 | 2 | 3 | 3.5 | 4.5 | 6 | 6 | |||

| Overall power (kW) | 1.08 | 1.35 | 2.3 | 3.1 | 3.8 | 4.8 | 6.3 | 6.3 | |||

| Rotation speed (rpm) | 20-180 | 10-280 | 20~ 140 | 20~ 140 | 20~130 | 20~130 | 20~130 | 20~130 | 20~ 110 | 20~110 | |

| Power of motor (W) | 25 | 40 | 250 | 60 | 250 | 180 | 250 | 180 | 250 | 370 | |

| Condenser | Vertical type dual-cooling coils | Vertical type, Main + auxiliary | Vertical type, Main + auxiliary triple: cooling cold traps | ||||||||

| dual-cooling cold traps | |||||||||||

| Condensation area (m*m) | Main | 0.126 | 0.126 | 0.278 | 0.39 | 0.948 | 1.15 | ||||

| Auxiliary | 0.253 | 0.358 | 0.4 | ||||||||

| Bath material (mm) | Stainless steel 304 250*130 | Stainless steel 304 254*130 | Stainless steel 304 300*170 | Stainless steel 304 370*220 | Stainless steel 304 450*260 | Stainless steel 304 550*320 | |||||

| Temperature range | Room temp +5°C ~ 95°C | ||||||||||

| Temperature display | Digital display | Digital display | LCD | Digital display | LCD | Digital display | LCD | Digital display | LCD | Digital display | |

| Vacuum Leakage | ≤2kPa/h | ||||||||||

| Evaporating speed (L/h) | Water | 0.9 | 1.4 | 2 | 3.2 | 5 | 9 | ||||

| Ethanol | 1.2 | 5.4 | 8.6 | 14.3 | 24.5 | ||||||

| Lifting function | Manual lift | Manual lift | Motorized lift | Manual lift | Motorized lift | Manual lift | Motorized lift | Manual lift | Motorized lit+ Manual lift | Manual lift | |

| Elevating stroke (mm) | 0~ 150 | 0~ 150 | 0~ 150 | 0~ 160 | 0~190 | 0~ 180 | |||||

|

Dimensions (cm) W*D*H |

64x 40x 92 | 62x 40x 85 | 84x 52x 114 | 104x 58x 180 | 112x68x190 | 119x74x204 | 134x 77 x 223 | 134x 70x 223 | |||

| Explosion-proof control box dimensions (mm) | 500Wx455Dx985H | 500Wx455Dx985H | 500Wx455Dx985H | 500Wx455Dx985H | |||||||

| Net weight (kg) | Main machine | 13 | 13.5 | 35 | 60 | 61 | 85 | 90 | 115 | 140 | 200 |

| Explosion - proof control box | 58 | 58 | 58 | 58 | |||||||

| Recirculating Chiller | Rotary Evaporator | vacuum Pump |

| DOVMXtech-RC30-300 | DOVMXtech-1005CE | DOVMXtech-WCVP-B95 |

| DOVMXtech-RC30-700 | DOVMXtech-1010CE | DOVMXtech-WCVP-B95 DOVMXtech-DVP-401 |

| DOVMXtech-RC30-1000 | DOVMXtech-1020CE | |

| DOVMXtech-RC30-2500 | DOVMXtech-1050CE |

DOVMXtech offers reactors ranging from 10 liters up to 300 liters, with Stainless Steel Reactor and Glass Reactor options. The reaction material is placed in the inner container of the jacketed glass reactor, and at the same time, it can be vacuumed and stirred at a speed. Heating and cooling media can be introduced into jacket layer for controlling apparatus temperature. This is a way for controlling heat transferring of apparatus temperature in lab, pilot and production process in chemical, biochemical and pharmaceutical industry.

Lab Scale Glass Reactor Solution

| Temperature-Control System | Glass Reactor | Vacuum Pump |

| DOVMXtech-CC-400 DOVMXtech-CHC-5-200-30H |

GR-1L | DOVMXtech-WCVP-III DOVMXtech-DVP-201Z |

| GR-2L | ||

| GR-3L | ||

| DOVMXtech-RC30-300 DOVMXtech-CHC-5-200-30H |

GR-5L | |

Pilot Scale Glass Reactor Solution

| Temperature-Control System | Glass Reactor | Vacuum Pump |

| DOVMXtech-HC-20-250 | GR-20L | DOVMXtech-WCVP-B95 DOVMXtech-DVP-401 |

| DOVMXtech-CC-20-80 | ||

| DOVMXtech-CHC-20-200-30/40/80H | ||

| DOVMXtech-HC-50-250 | GR-50L | |

| DOVMXtech-CC-50-80 | ||

| DOVMXtech-CHC-50-200-30/40/80H | ||

| DOVMXtech-HC-100-250 | GR-100L | |

| DOVMXtech-CC-100-80 | ||

| DOVMXtech-CHC-100-200-30/40/80H |

we also provide turnkey solution for Hemp Oil CBD, Fish Oil or Plant Essential Oil extraction and technical support.

DOVMX TECHNOLOGY CO., LIMITED

We will serve our overseas customers with professional technical support, enthusiastic service attitude, good overseas sales experience and efficient communication. Provide them with reliable quality and worry free after-sales equipment solutions.

If you want to speed up the service, please contact us:

WhatsApp/Skype +852 51756923 or info@dovmxtech.com

......